The New Development of Stamping Technology on Automobile

The new development of stamping technology has closed relationship with materials and structure. In the next 10 to 15 years, the higher environmental requirements and increasingly stringent environmental protection laws will force automobile materials and structure to change a lot. In order to reduce carbon dioxide emission, automobile strives to light weight. The most prominent development is to improve specific strength and stiffness of materials and develop high efficient light weight structure. On modern automobile structure, high strength steel accounts for about 25%. At present, continue developing ultrahigh-strength steel and meanwhile combine with developing new high efficient structure and manufacturing technology, endeavoring to make body weight reduce to more than 20%. However, expanding application of aluminum and magnesium having low density on automobile attracts more attention.

Europe and America are focusing on developing aluminum automobile body, reducing weight by 40%-50%. The oil consumption is only 1/3 of current average consumption of automobile. Nowadays, the main obstacles are developing low cost aluminum alloy, new structure, high efficient manufacturing technology and improving recycle technology. Once the cost is figured out, aluminum may become the main materials for automobile structure.

Since 1991, the output of magnesium has already increased by one time every 5 years, having a bright future. It is predicted that the application of magnesium will rise significantly including large body external parts.

Structure integration is also an important development trend. The application of structure integration on automobile will be expanded in the future, not only just for aircraft.

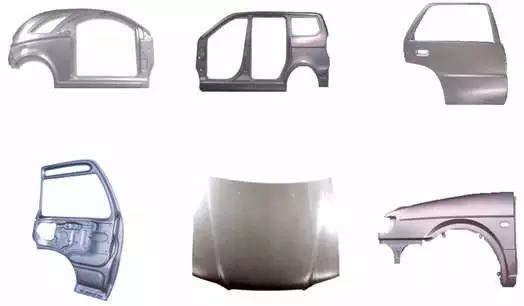

For the application of new materials and structure expanding, developing low cost stamping technology is necessary. The current research priority is stamping technology for aluminum alloy covering parts or other body parts.