Surface Modified Techniques for Forging Mold

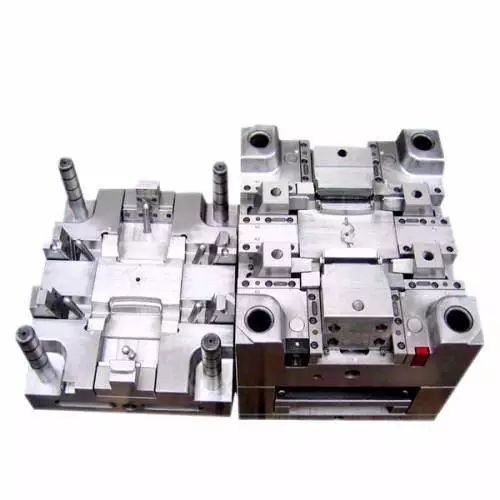

Mold forging refers to that heat metal into liquid or soften. Then put the metal into mold, modeled for one-time by up and down mold. Sometimes it requires several time. The difference that casting requires heated metal to be directly poured into the mold while mold forging needs up and down mold closing. Due to suffer from the extrusion force during forming, tissue and mechanical properties of forgings are better than castings.

The heat treatments that use modern technology to change materials surface, ingredients of sub-surface, tissue and performance of forging mold are called as surface modified techniques are, mainly containing the following ten categories:

1. Electrochemical conversion

The technology that oxide film is formed on the surface of parts in electrolyte solution or under the action of external electric is called as electrochemical conversion modified technique. In engineering, electrochemical conversion modified technique is also called as anodic oxidation or anodizing. In recent years, one development of electrochemical conversion technique is micro-arc plasma anodizing. It can significantly improve the hardness on surface or form new film decorated by color, having good application in mold industry.

2. Surface deformation strengthening

Use shot blasting, extrusion, laser shock, rolling, ultrasonic shock, vibration shock, high-pressure spray and other techniques so that elastic-plastic deformation can occur on surface of materials. Import residual compressive stress or change microstructure to enhance fatigue resistance and corrosion resistance of materials, improving stability and durability of parts.

3. Surface phase transformation strengthening

Use electron beams or laser beam to rapidly heat the surface of materials, forming phase transformation zone on surface or sub-surface so that can form particular surface layer having fine tissue and strengthening phase.

4. Ion implantation

Use ions ionized by vacuum system and directly inject ions into surface of materials, accelerated by high voltage. Then, form very thin ion injection layer, which change the composition and tissue of materials surface, improving the performance of materials surface.

5. Organic & inorganic coating technique

Organic coating technique means that use coatings (oil paints, pain vehicles, pigments, thinners) to add particular protection, decoration and flame resistance, chameleon and other performances on the surface of parts.

Inorganic coating technique refers to form inorganic cover layer or surface film on the surface of metal. Inorganic cover layer or surface film has specific chemical constitution, tissue and morphology which can add new performances to matrix and coating.

6. Surface alloying

Deposit metal or nonmetal on the surface of matrix materials, then metal or nonmetal permeates into the surface of matrix materials through diffusion, changing chemical constitution and phrase of surface of matrix materials, improving usability of surface of materials.

7. Chemical conversion

Put metal into chemical solution, and form a film of passive compound on the surface. improving the performance of surface. In engineering, commonly used films of passive mainly contain chromate, phosphate, oxalate and enamel on the surface of steel parts. Besides, in engineering, techniques which reduce roughness of surface (polishing, buffing and roll finishing) and surface coloration are also attributed to chemical conversion.

8. Metal electrochemical position

Metal electrochemical position refers to that a layer or multi-layer of metal coating, alloy coating or composite coating are deposited on the surface of metal parts by using electrochemical method. The technique is also called as electroplating. Using electroplating can forms various coatings having different functions on the surface of metal parts.

9. Rust protection

Metal occurring chemical or electrochemical changes under the effect of environment is called as metal corrosion, also known as rust or corrosion. Rust protection is a technique that protects metal from being corroded during manufacturing, carrying, transportation, storage and application.

10. Hot dip coating

Hot dip coating also called as hot dip is a technology that metal metallic coating materials are soaked in other liquid metals or alloys having lower melting point, then, form coating. The feature of hot dip coating is that an alloy layer is formed between matrix metal and coated metal.