What Makes Drop Forging Best for Industrial Metal

What Makes Drop Forging Best for Industrial Metal Components? Drop, press, rolling, hot, cold, warm; there is a wide variety of processes that forging materials can take to manufacture parts for...

What Makes Drop Forging Best for Industrial Metal Components? Drop, press, rolling, hot, cold, warm; there is a wide variety of processes that forging materials can take to manufacture parts for...

Stainless Steel Drop Forgings CT Drop Forge is the expert in closed die drop forging, stainless steel is one of the main steel forging materials we can forge to meet special specifications....

How to Select Forging Materials? The material that is selected for forging process must be one that can achieve the required physical and mechanical properties. Where alloys from several groups...

Hot Forging In terms of temperature, there are different types of forging: hot forging, warm forging and cold forging (refer to cold forging vs warm forging vs hot forging). Hot forging is the most...

Hot Forging In terms of temperature, there are different types of forging: hot forging, warm forging and cold forging (refer to cold forging vs warm forging vs hot forging). Hot forging is the most...

Forging vs. Casting Forging and casting already become the two main metal forming processes for all kinds of industries. Today, we would like to discuss the differences between forging and casting in...

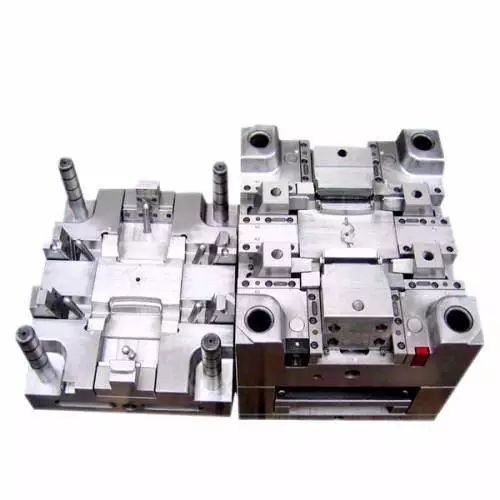

Several key technologies are used for simulation software of stamping 1. Geometric and mechanic model of mold Mold has higher rigidity than sheet. In general, mold is used as rigid body. When referring...

China has the largest output of die forgings in the world. These die forgings mostly use hot die forging manufacturing. Auto die forgings output in China accounts for about 67% of total output of die...

Forging is process that metal is flatten, thumped or extruded for acquiring high strength. In general, the metal should be preheated to the prospective temperature before forging. What should be noticed...

With people’s living standard constantly rising, Chinese auto industry shows rapid development tendency. Car parc grows annually. Meanwhile, requirements for auto security are higher and higher. ...

Mold forging refers to that heat metal into liquid or soften. Then put the metal into mold, modeled for one-time by up and down mold. Sometimes it requires several time. The difference that casting requires...

Precision forging technology is a kind of technologies that the dimension of components can meet the accuracy requirements with no or less processing after being forged. There are two main paths for precision...