Quality Control

Control Systems:

ISO 9001, TS 16949.

QC Staff:

45 to 60.

Materials/Components:

Materials/Components:

- Supplier assessment.

- Incoming material inspection.

- Traceability system.

Procedures/Testing Details:

SPC (Statistical Process Control): Monitoring of variables and attributes using control charts during production.

Part evaluation: Inspection of the final piece at the end of each production run.

Final audit: Random sampling from each shipment lot to ensure compliance with key specifications.

Other Information:

- Control plan for parts.

- Process flowchart.

- Process Failure Mode and Effects Analysis (FMEA).

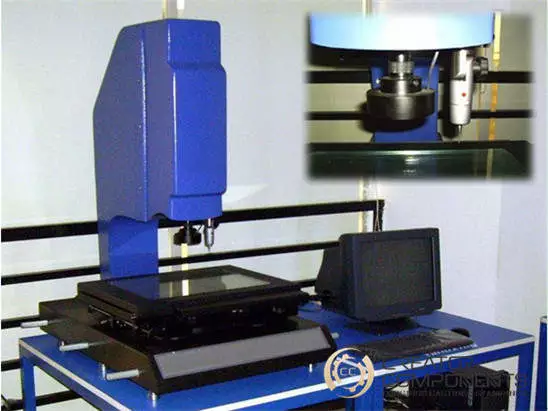

- A full metrology review of the key parameters.

- A full dimensional layout.

Next: Major Customers

Previous: Company Profile