What Makes the Forging Process Indispensable?

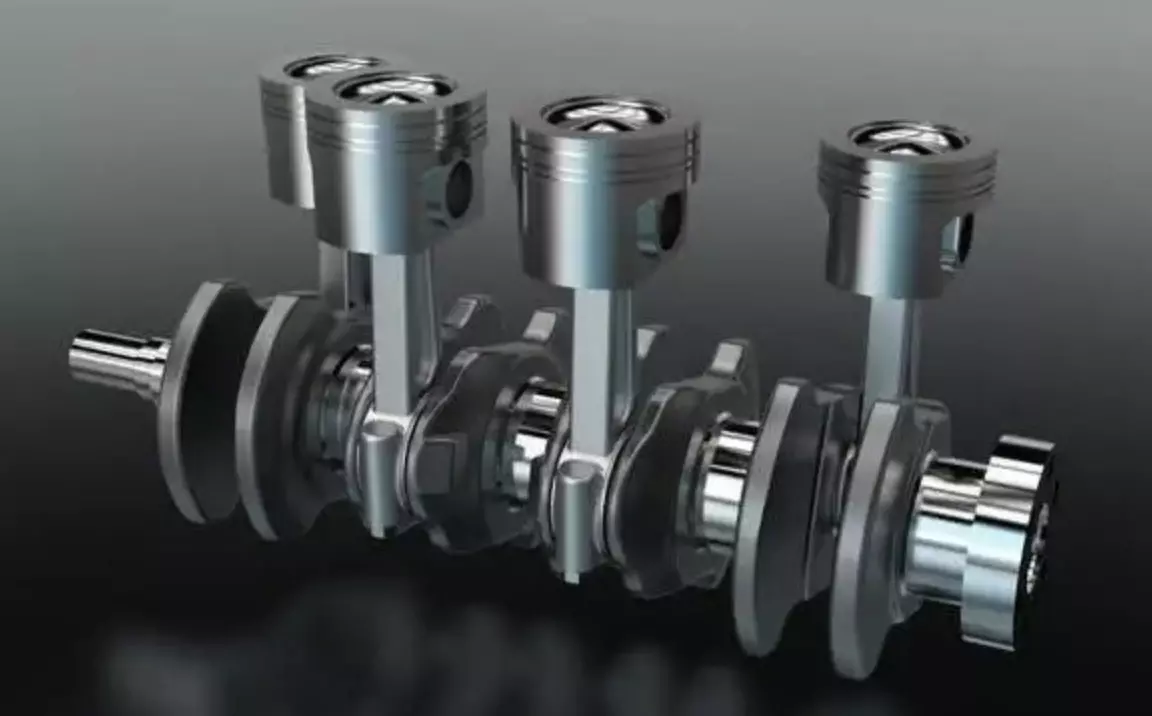

The significance of the forging process remains unparalleled in various industries, particularly in the automotive sector where components like crankshafts demand exceptional strength and precision. Forging stands out as a pivotal method for shaping block and bar steel, employing the force of strikes to mold materials into desired forms. Notably, hot forging, performed at temperatures above the recrystallization point, yields superior mechanical properties and near-final product shapes, making it...