How to Drop Forging Production Efficiency

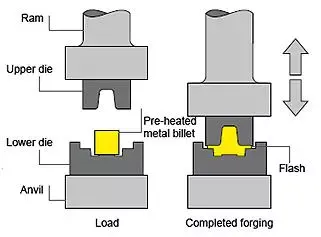

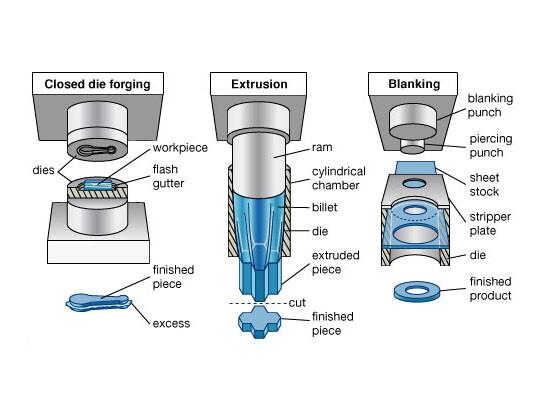

In manufacturing, various techniques are employed to produce high-quality parts and components, and one such technique is drop forging. This method creates strong and durable metal parts by heating metal to a high temperature and then using a hammer or press to deform it into the desired shape. Named "drop forging" because the metal is dropped into the forging machine, this process is widely used in industries such as automotive, aerospace, and construction. To leverage the benefits of...