An Overview of Precision Forging Types and Its Applications

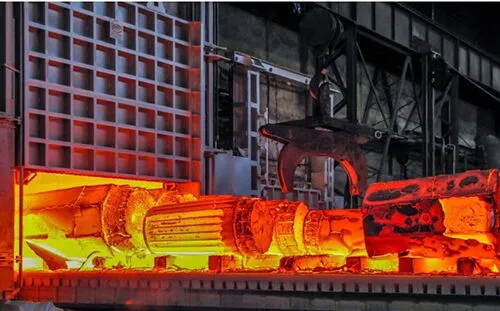

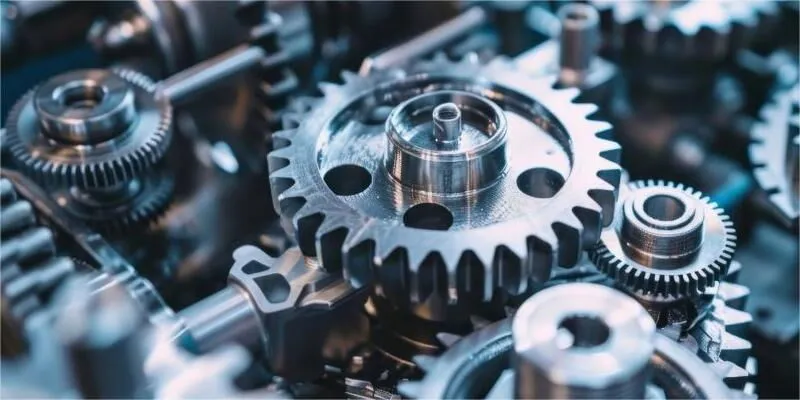

Precision forging is a modern manufacturing process that shapes metal components with minimal or no need for further machining, meeting strict requirements for parts usage. This technique finds widespread application across various industries, including automotive, mining, energy, construction, aerospace, and weapons manufacturing. With advancements in technology, precision forging is becoming an efficient, energy-saving, and environmentally friendly manufacturing solution. It significantly conserves...