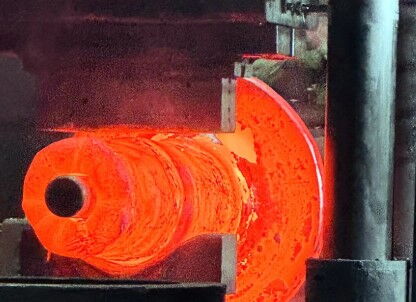

Ring Rolling Process: Efficient Production of Ring Forgings

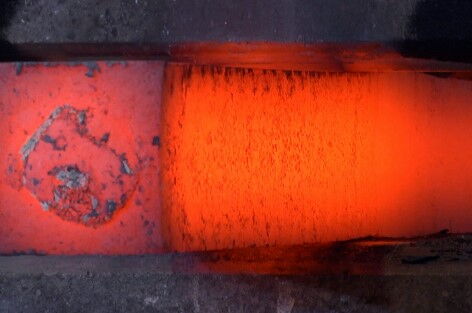

Ring rolling, also known as ring expanding, is a crucial process for manufacturing ring forgings. It involves rolling a ring-shaped blank on a specialized ring rolling machine using rotating dies to simultaneously expand the inner and outer diameters of the blank while reducing the wall thickness, thereby forming the desired ring forging. This process is not only suitable for mass production but also enhances production efficiency and machining accuracy. Below, we will provide a detailed introduction...