Why is Product Inspection Necessary in Drop Forging?

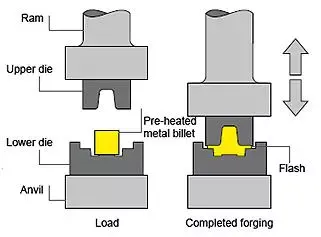

In the manufacturing industry, especially in key industries such as automotive and aviation, drop forging is an important metal forming technology. This technique uses gravity or power-driven hammering to forge metal billets into the desired shape and size. Although drop forging is an efficient production method, quality control in the process is equally important. Product testing plays a key role in ensuring that the final product meets design specifications and performance requirements. Product...