Why is Forged Aluminum Suitable for Handlebar Risers

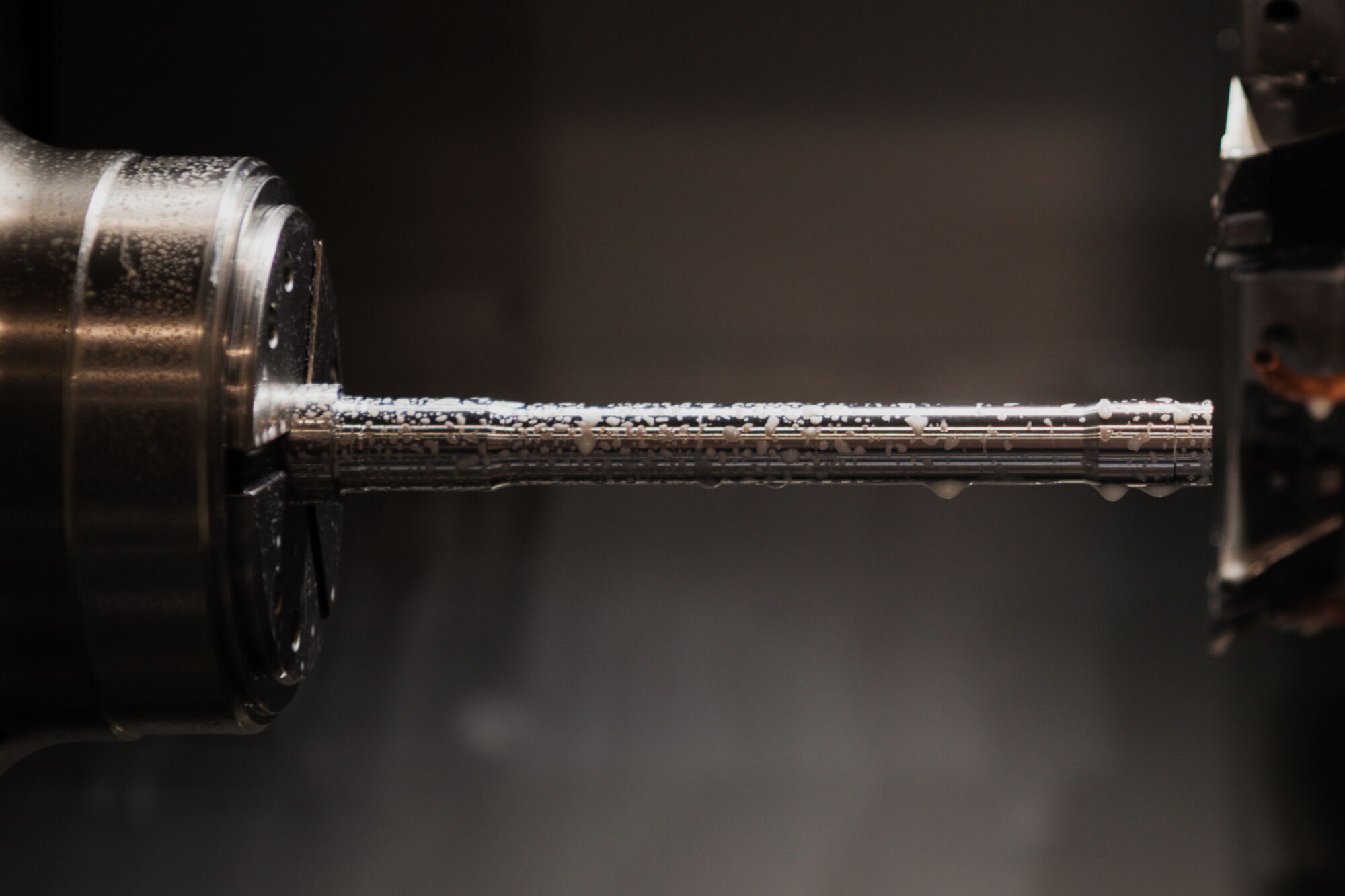

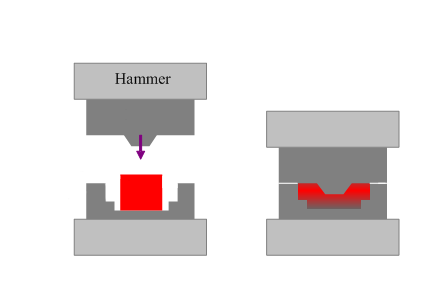

Aluminum is a lightweight, versatile metal that is favored in manufacturing because of its outstanding properties. Motorcycle handlebar risers are one of the typical applications of aluminum products in the field of transportation. The handlebar riser is the connection between the handlebar and the front fork of the motorcycle, which has a crucial impact on the handling and ergonomic design of the vehicle. In recent years, forged aluminum has become the preferred material for motorcycle handlebar...