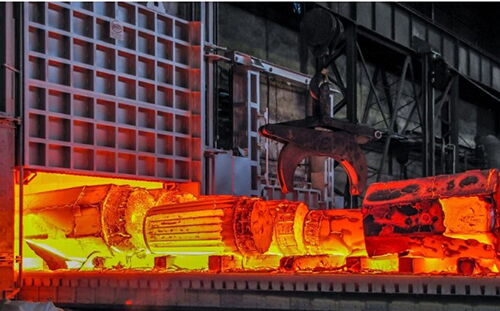

Forging Process and Requirements for Shaft Components

Shaft components are crucial foundational parts in mechanical equipment, widely used in core functions such as transmission, support, and torque transfer. These components typically endure significant loads and operate under complex conditions, placing extremely high demands on their manufacturing precision and mechanical properties. Forging, as a key process in the manufacturing of shaft components, effectively optimizes the internal grain structure of the material, enhancing the strength, toughness,...