Treatment of Folding Defects in Forged Aluminum Alloys

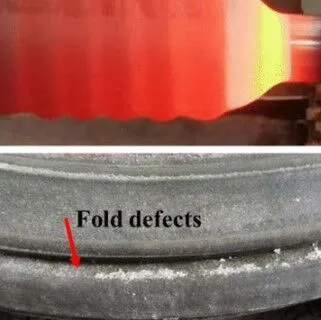

During the forging of aluminum alloys, a common issue that can arise is a defect called "folding", which occurs due to oxidation during the deformation process. Folding happens when oxide scale builds up on the surface and causes the metal layers to merge together. This defect typically appears on the surface of the metal. If not addressed in time, folding can negatively affect both the mechanical properties and the appearance of aluminum alloy parts. In this article, we'll explore...