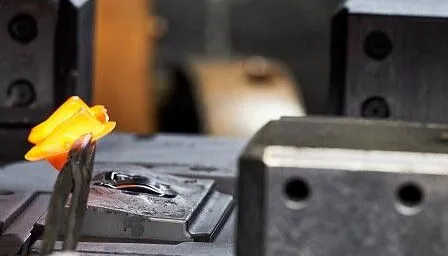

The Defects of Forged Components and Improvement Measures

Forging is one of the most common and widely used processes in metalworking industries. Known for its high strength and excellent plasticity, forged components are crucial in various sectors such as aerospace, automotive, metallurgy, chemicals, and energy. However, despite its advantages, the forging process can sometimes lead to various defects in the final product. These defects can negatively affect the appearance, performance, and, in some cases, the safety of the forged components. As a result,...