Key Specifications / Features

Tags

Detail Information

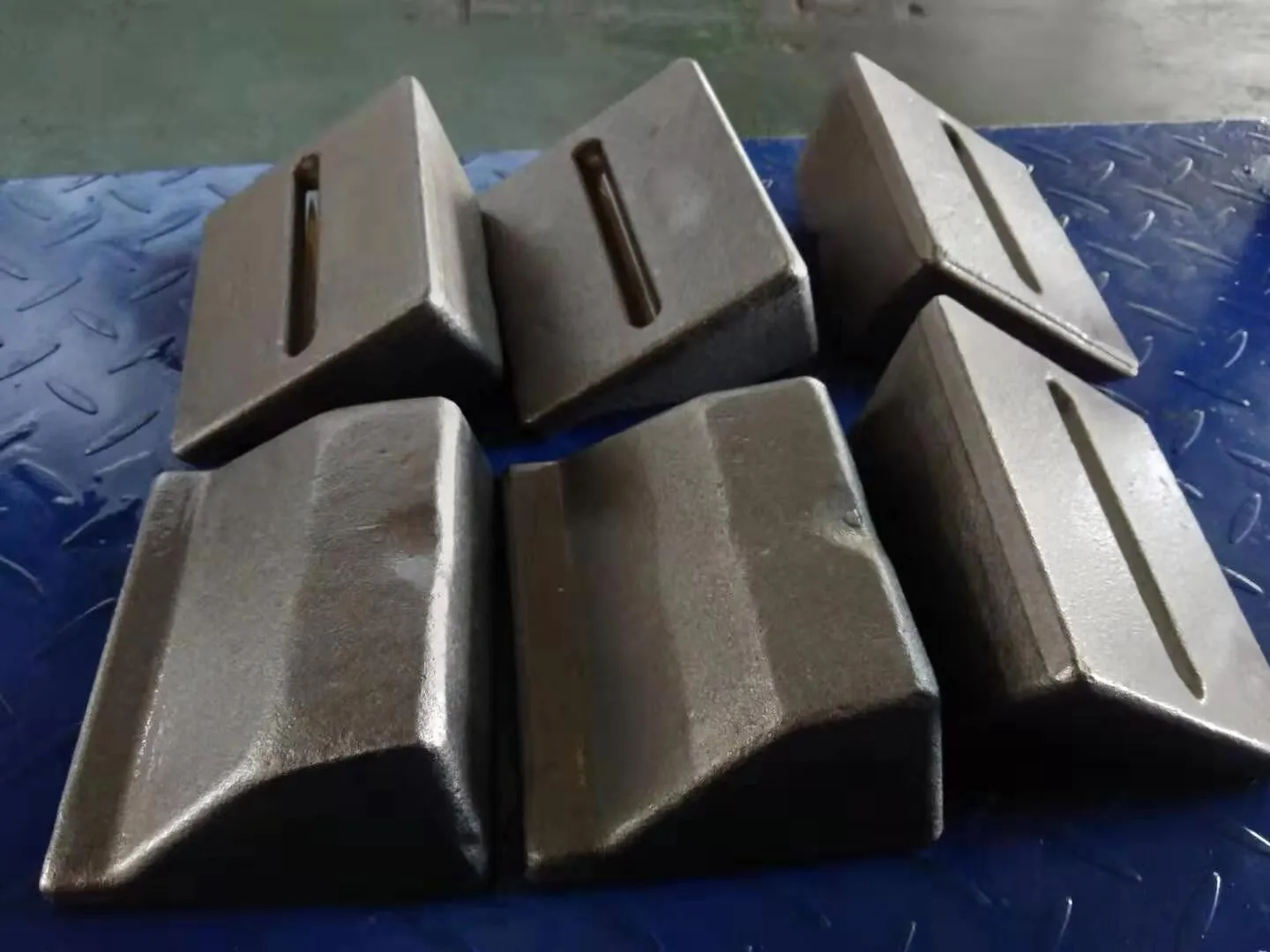

Parts Name: Closed Die Forged Rain Train Parts

Type: Carbon Steel Forging

Materials: Carbon Steel, ASTM 1035, ASTM 1045, ASTM 1021, ASTM 1040, ASTM 1320 / 20Mn2, ASTM 1340 / 40Mn2, ASTM 5120 / 20Cr, ASTM 5140 / 40Cr, ASTM 4119 / 20CrMo, ASTM 4140 / 42CrMo, ASTM 4135 / 35CrMo, ASTM 4340 / 40CrNiMo, DIN ST52-3 / Q355 / 16Mn, etc.

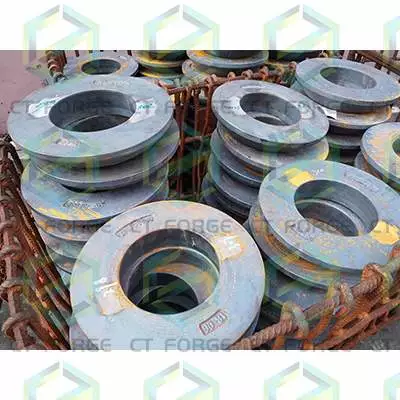

Forging Method: Closed Die Forging, Roll Ring Forging, Drop Forging, Hot Forging

OEM No: Customized

Weight: 1-100 KG

Dimension: Customized

Heat Treatment: Normalizing, Quenching and Tempering

Test: Magnetic Powder Defects Test, Hardness Test, Dimension Test

Application: Train

Alloy Steel Drop Forgings

Alloy steel is also one of the most commonly used metals for drop forging. This is because drop forged alloy steel is known for being stronger, more wear resistant and tougher compared to carbon steel drop forgings. Alloy steel is considered to be iron-based alloys that has been alloyed or mixed with a variety of elements in the range of 1.00 – up to 50.0% to enhance the physical properties. The combination of alloys and elements forged together is what determines the phyical strengths and properties of the metal. Common alloys added are chromium, molybdenum, manganese, nickel, vanadium boron and silicon.

To achieve these properties of increased stregnth, resistance and toughness, alloy steel drop forging is typically done by heat treatment,also known as hot steel forging. Our company maintains an extensive inventory of alloy steel. Our most popular closed die alloy steels to forge include 20Cr, 20CrMo, 30CrMo, 35CrMo, 42CrMo, ect.

These are some basic alloying descriptions:

Adding manganese, silicon, nickel and copper to the alloys results in an increase in strength by forming solid solutions in ferrite which is ideal for extreme heat exposure.

Chromium, vanadium, molybdenum and tungsten increase strength by forming second phase carbides.

Nickel and copper improve corrosion resistance.

Molybdenum helps to resist embrittlement.

There are many alloy steels and elements to choose to forge at our company. Drop forged alloy steel is used in many applications such as agricultural, aerospace and special machinery. A good rule of thumb is to keep in mind that the industry dictates what alloying may be necessary to achieve desired properties, along with proper heat treatment of parts.